Coronavirus and the Painting Industry

Daniel Wurm | 15 Mar 2020

By the time you read this article, you will already have started to see the effects of the coronavirus on your daily life. The virus is technically called COVID-19, as there are many types of coronavirus, but the COVID-19 variant is the one that emerged in China late last year and is now a world-wide pandemic.

How dangerous is it?

At the time of writing the World Health Organisation has provided data that shows that approximately 20% of everyone who contracts the virus will need to be hospitalised, and between 3 - 4% of people who contract it may die. This makes it over 20 times more dangerous than the flu (the flu has a mortality rate of .1% )

When you combine this with the fact that it is twice as contagious as the flu (the average person who contracts the virus passes it on to approximately two other people, vs the flu which is usually only passed onto an average of one other person), you can quickly see how dangerous it is and why the government is taking drastic measures to keep it contained.

The demographic who seem to be the most at risk of fatalities are people over the age of 60, and anyone with a pre-existing health condition, such as diabetes, or lung problems.

The impact of coronavirus is wide ranging within the painting industry, from effects felt within the supply chain, through to the inevitable questions about its impact on employment conditions and safety.

Impact on painting businesses

You don’t want to have people in close proximity to each other, but you can be on a jobsite and not be within 1.5m of each other. Those who are immunocompromised should consider whether they should stay home depending on what their tasks are.

In preparation for increased absenteeism, supervisors should cross-train employees to handle other functions.

It can also be helpful to encourage workers to develop contingency plans for child care in the event of long-term closures of schools and daycare centers.

In addition to clarifying or amending sick-leave policies and encouraging work-from-home for all employees who can be productive working off-site, painting companies can be proactive in communicating potential delays due to coronavirus-related issues. The important thing to do is communicate potential impacts on schedules. Let the builders or owners know, ‘We have an issue with a handful of people staying home, this is what we expect the delays to be.’

It could be the case that in the near-future a project owner or builder will say that the risk is too great to continue work if the site is near to where there are more cases, or close to a medical facility or an area where the exposure risk is high. Emergency protocols within affected communities, could trigger a variety of challenges. If public transportation shuts down or schools close, many employees may find it difficult or impossible to show up for work.

For more information on your responsibilities as an employer, click here

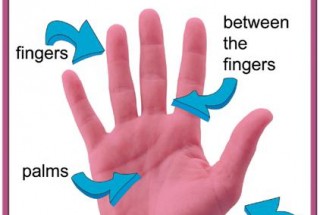

Training Your Staff in Hygiene

Above: there are now dozens of high quality training videos for training staff in hygiene practices

It is critical that painting company supervisors and employees train their staff in strict hygiene, particularly when doing repaints on residential and commercial projects. Painters are required to handle door furniture, window furniture, doors, architraves, and many surfaces which are perfect for transmitting the virus. It is important to sterilise all these surfaces on completion, and to avoid sharing tools such as brushes and roller poles without sterilisation.

In addition to physical wellness, employers should consider mental health, too, because employers report anxiety among workers as one of the top issues brought on by the coronavirus.

To assist you to do this quickly and efficiently, the National Painting and Decorating Institute has created an easily understandable and affordable on-line COVID-19 Infection Control Accreditation Course, in association with the Australasian Infection Control Society, and Biological Services Australia. It contains important facts and information from the World Health Organisation, the Federal Department of Health, and WorkSafe Victoria, and is created in such as way to ensure that workers understand the information. Topics covered include:

- Who is at risk?

- How to carry out proper hygiene practices

- How to disinfect surfaces

- How to self-isolate

- Business continuity planning

- Safe Travel procedures

We recommend putting all your staff through this course as soon as possible. Although a lot of information is freely available on the internet, employers should not rely on their employees finding the correct information themselves, and simply reading it. It is vitally important that they show they understand it; it could be a matter of life or death for some people.

The course can be completed from home on any internet connected device, including phones, tablets, laptops or PCs, and can translate into over 35 languages.

Employees who complete the course are issued with a certificate to prove they completed it. The course takes between 1 - 2 hours to complete.

To access the course click here

Impact on the painting industry supply chain

According to the Master Builders Association, "The impact of the coronavirus on the building supply chain in Australia is already starting to be felt. While the true impact won’t be known for weeks or possibly even months, we anticipate it will most likely be felt in the second half of 2020. The impact will be felt in both commercial and residential sectors; neither is immune. The building industry uses building products imported from China (particularly taps, valves, glass, nails, screws, nuts, bolts, iron and steel) and with the industry already facing a downturn, there is real concern about the impact this will have and the risk the industry will be exposed to."

The rush on purchasing of disposable masks, which are used within the industry as a control measure for dust, has also had an impact on the building industry.

Most brushware and accessories are manufactured in China, and Chinese factories are only going back to work now, after weeks of shut-down.

We contacted all major paint accessory manufacturers about how they expect it to impact their supplies, but only UniPro replied to confirm that:

"We source from many countries including China, but also locally from Australia and other regions including Indonesia, India, USA, Malaysia, Taiwan and so on. In relation to China specifically, the nature of our customer base in Australia means we do hold deep stocks to ensure consistent supply at all times. At the moment we are fully in stock of all lines and this will continue for the coming months. Our supply partners in China are hopeful to have new shipments on the water in the coming weeks to replenish our warehouses."

The suppliers of raw materials for paint manufacturers have also been impacted. We contacted Dulux, Haymes, Taubmans, Wattyl and Ecolour to confirm if they had supply chain issues.

Dulux replied to confirm the following:

For painters experiencing delays, our advice is to:

- Look at alternative sources for products – although, there will be no escaping a global supply issue.

- Investigate alternative products that are available in Australia. You will need to have your client’s approval to use an alternative product so ensure you follow the process set out in the contract for variations before you order an alternative product.

- Check with suppliers before placing orders and be clear on when to expect deliveries. Ensure you read your supplier agreements to understand what your rights are if goods are not received by the date that you have requested and agreed with the supplier.

- Ensure you manage delays caused by non-supply of products contractually and in writing. The key is to notify your client as soon as you become aware that a delay is likely to occur to the project and ensure that your notice of delay complies with the requirements of the contract. Submit updated notices of delay to keep your client abreast of a continuing delay and what steps you are taking to mitigate the delay.

- Ensure you submit a claim for an Extension of Time to the Date for Practical Completion within the timeframes noted in your contract. For domestic building work, this must be done within 10 business days of the delay occurring. For commercial/subcontract work, this is likely to be set out in the contract.

For new contracts, factor in delays wherever possible and be aware that it is unlikely that you will be automatically entitled to an extension of time to the Date for Practical Completion if the delay could have been reasonably expected at the time you entered into the contract or submitted your tender. We recommend that you raise the issue of supply delays with your client prior to submitting your tender and/or entering into the contract. Similarly, ensure that any quotes that you provide also address these potential issues.

First step when considering mask shortages – look at all other respiratory options, for example, re-usable masks or respirators.

Switch to On-line and On-site Training

Above: You can access virus-free apprenticeship training from colleges using the NIPD e-learning system

With many institutions such as schools, universities and TAFEs set to close due to virus containment measures, smart employers are switching to training providers that use the National Painting and Decorating Institute's on-line training system, which allows apprentices to study on-line without having to attend classes.

This system is a much safer way to train staff, and offers no disruption to the training plan, as apprentices can study at home or on-the-job, using social distancing measures. The practical part can be taught on the job in small groups. To find out which RTOs and training colleges are offering this option in your state or territory, contact the National Painting and Decorating Industry.

Employment conditions & safety – common questions

If you’re an employer within the industry, you need to be across the questions you may be asked regarding coming to work and workplace risk management, according to Australian workplace laws.

Workers and their employers must follow the government guidelines regarding self-quarantine periods, with workers required to notify their employer should self-quarantine be required.

Employers are also responsible for identifying and managing work health and safety risks, which includes exposure to the virus. Businesses and their workers should be familiar with how to prevent the spread of infection.

Employers should consider measures such as providing hand washing facilities or alcohol-based hand sanitiser, tissues and cleaning supplies and generally promoting good hygiene practices. It is now critical that all employers provide sanitiser to employees for sanitising PPE such as respirators, hard hats and safety harnesses.

Questions concerning medical and testing issues must be raised with the appropriate authorities and medical experts.

What if an employee is not sick but wants to stay home as a precaution?

Employees will need to make a request to work from home (if possible) or take some form of paid or unpaid leave, such as annual leave or long service leave. These requests are subject to the normal leave application process in the workplace.

What if an employee is not sick but is in a period of self-isolation / quarantine arising from government directions?

If, (due to recent travel or contact) an employee is subject to the government direction to self-isolate /quarantine, they MUST stay at home for the duration. Employees are not entitled to payment of wages, but the employer may agree to some form of paid leave such as annual leave or long service leave. This also applies to overseas quarantine.

What if an employer wants their staff to stay home (not working)?

Where an employer directs a full-time or part-time employee not to work, the employee would ordinarily be entitled to be paid while subject to the direction. You should consider your obligations under any applicable enterprise agreement, award, employees’ contracts of employment, and workplace policies.

What if a customer closes a site or prohibits my employee from attending because of the customers concerns?

Where possible the employer should try to assign the employee to work elsewhere.

Can an employee be ‘stood down without pay?

Under section 524 of the Fair Work Act an employee can only be stood down from work without pay if they can’t do useful work because of equipment break down, industrial action or a stoppage of work for which the employer can’t be held responsible. The most common scenario of a stoppage usually involves a natural disaster or power outages. Employees may be required to undertake alternative duties to avoid stand down, provided that in all circumstances it does not change the ordinary wages.

Stand down is most often limited to short term stoppages.

The right to stand down does not require the employer to prove that no employees can perform useful work. It may be limited to a part of the enterprise. Note that this limited stand down may pose workplace relations concerns across the workforce.

Business disrupted due to lack of supply

If a shortage of work is due to a sudden failure of supply of components which are essential to the business operations, this may be grounds for an employer to stand down employees without pay.

Before the decision is made to stand down, the employer must take all reasonable steps to source alternative suppliers.

Business disrupted due to absent employee

There may be very limited circumstances where the employer cannot provide useful work to its workforce because of the sheer number of employees on quarantine or on leave.

Before the decision is made to stand down, the employer must take all reasonable steps to source alternative labour.

Business disrupted due to customer not accepting employee

There may be circumstances (for example in a small business that focuses on repaints) where the employer cannot provide useful work for an employee because a customer refuses to allow the employee on their premises.

Before the decision is made to stand down, the employer must take all reasonable steps to source alternative work for the employee.

Some businesses will be eligible to tax relief and other subsidies e.g. for employing apprentices.

More information

https://www.health.nsw.gov.au/Infectious/diseases/Pages/coronavirus.aspx

https://www.worksafe.vic.gov.au/resources/preparing-pandemic-guide-employers